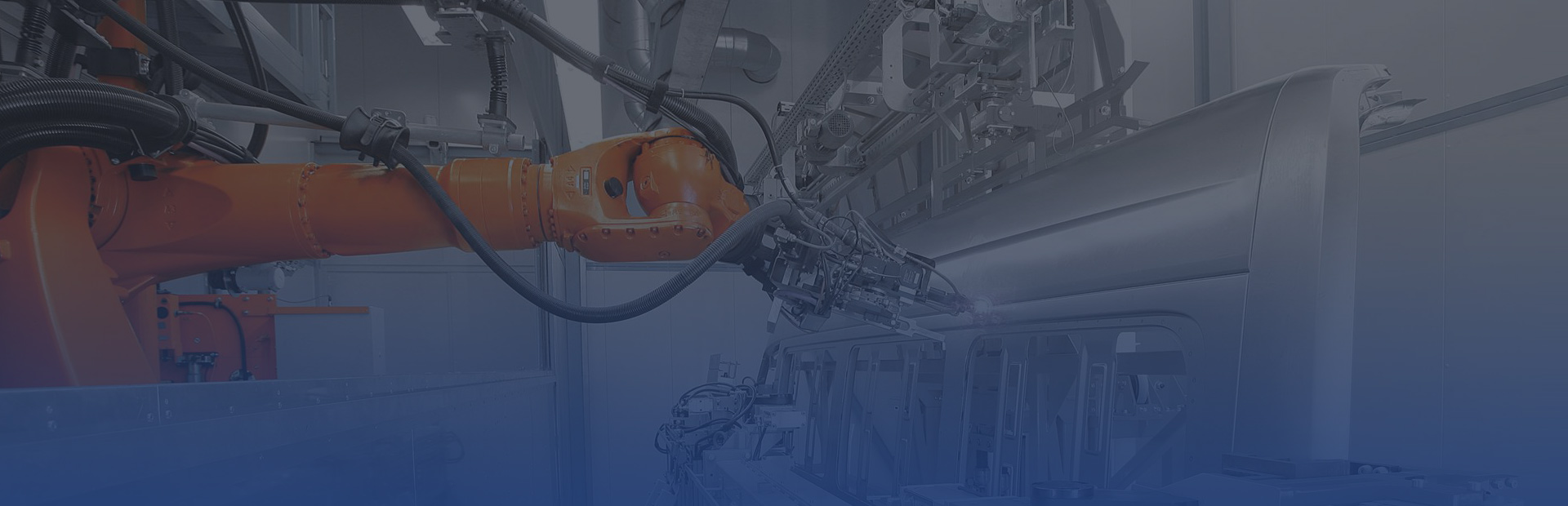

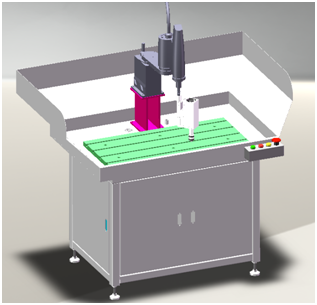

Robot tapping machine

Consult Immediately

National hotline: +86 0769-85832096

Details

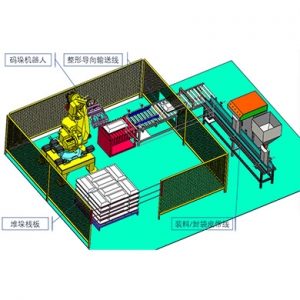

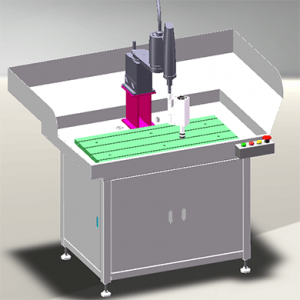

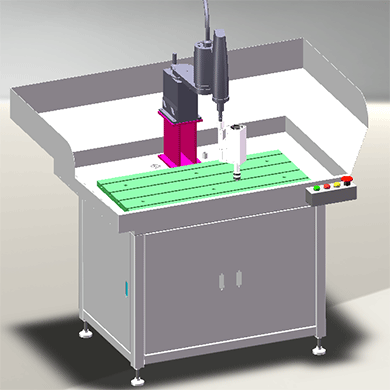

According to the automatic tapping demand of porous position in sheet metal and metal processing industry, the robot tapping machine is developed and produced. When working, it can be matched with the robot loading and unloading system. When the workpiece to be processed is put into the station fixture, it can be fed automatically, positioned automatically, clamped automatically, tapped automatically and unloaded automatically. One worker can operate multiple equipment at the same time, with high production efficiency and significant labor cost savings! It has the characteristics of novel design, reasonable structure, simple and easy to use, high degree of automation, convenient use, high efficiency, maintenance free and high cost performance. The processed threads have high finish and high qualified rate of finished products.

Product features:

1. 2-4 manual tapping machines with high productivity;

2. After the first teaching, there is no need to find the hole position manually to reduce the labor intensity; It will not miss tapping teeth and avoid quality loss;

3. Small floor area, easy to move and production deployment;

4. Simple structure and good stability;

5. Convenient product switching and simple programming;

6. Single phase 220V power supply, easy to use, low power consumption and power saving.

Main configuration and performance:

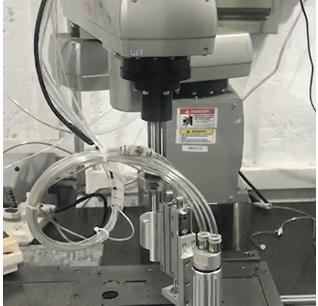

12. Robots: Yamaha, Epson, Denso, Staubli, four axes;

13. Tapping materials: aluminum, iron, stainless steel, etc;

14. Maximum tapping capacity: M1 5-m5, optional (maximum M8);

15. Maximum tapping depth: 60mm;

16. Tapping range diameter: 200mm-1200mm optional;

17. Driving mode: servo? Pneumatic;

18. Machining accuracy plus or minus: 0.1mm;

19. Control mode: robot control system.

Product features:

1. 2-4 manual tapping machines with high productivity;

2. After the first teaching, there is no need to find the hole position manually to reduce the labor intensity; It will not miss tapping teeth and avoid quality loss;

3. Small floor area, easy to move and production deployment;

4. Simple structure and good stability;

5. Convenient product switching and simple programming;

6. Single phase 220V power supply, easy to use, low power consumption and power saving.

Main configuration and performance:

12. Robots: Yamaha, Epson, Denso, Staubli, four axes;

13. Tapping materials: aluminum, iron, stainless steel, etc;

14. Maximum tapping capacity: M1 5-m5, optional (maximum M8);

15. Maximum tapping depth: 60mm;

16. Tapping range diameter: 200mm-1200mm optional;

17. Driving mode: servo? Pneumatic;

18. Machining accuracy plus or minus: 0.1mm;

19. Control mode: robot control system.

Previous:Robot bending workstation

Related articles

- Fan Cheng Tianji robot on duty: auxi···

- Fan Cheng Looking for Shenyang oppor···

- Detailed explanation of positioning ···

- Leaf vegetable factory starts automa···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng Focus on China and look ar···