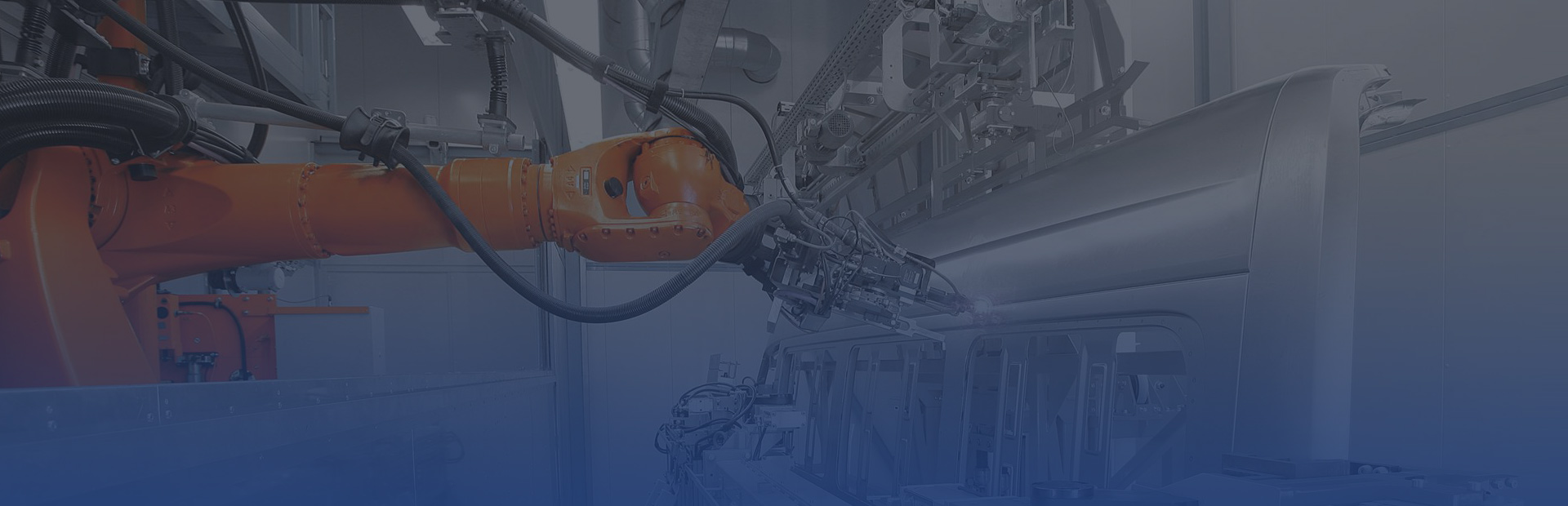

Robot welding workstation

Consult Immediately

National hotline: +86 0769-85832096

Details

Welding robot mainly includes robot and welding equipment. The robot is composed of robot body and control cabinet (hardware and software). The welding equipment, such as arc welding and spot welding, is composed of welding power supply (including its control system), wire feeder (arc welding), welding gun (clamp), etc. For intelligent robots, there should also be sensing systems, such as laser or camera sensors and their control devices. If the workpiece does not need to be displaced in the whole welding process, the workpiece can be positioned on the worktable with a fixture. However, in actual production, more workpieces need to be displaced during welding, so that the weld can be welded in a better position (posture). In this case, the positioner and robot can move separately, that is, after the positioner is displaced, the robot is welded again; It can also move at the same time, that is, the positioner moves while the robot welds, that is, the positioner coordinates with the robot. At this time, the motion of the positioner and the motion of the robot are combined, so that the motion of the welding gun relative to the workpiece can not only meet the requirements of the weld trajectory, but also meet the requirements of the welding speed and the posture of the welding gun. In fact, at this time, the axis of the positioner has become an integral part of the robot. This welding robot system can have up to 7-20 axes, or more.

Product features:

1. Stabilize and improve the welding quality, and can reflect the welding quality in the form of numerical value;

2. Improve labor productivity;

3. Improve the labor intensity of workers and work in harmful environment;

4. Reduce the requirements for workers operation technology;

5. It shortens the preparation cycle of product upgrading and reduces the corresponding equipment investment.

Main configuration and performance:

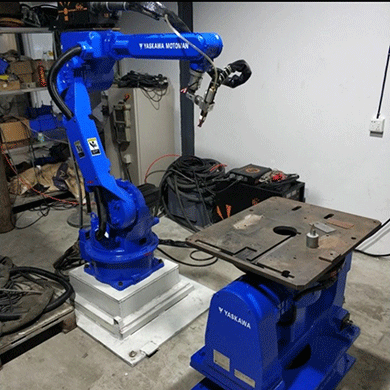

1. Robot: OTC, Panasonic, KUKA, abb, FANUC, Yaskawa, six axis

2. Welding materials: aluminum, iron, stainless steel, etc;

3. Welding methods: gas shielded welding, argon arc welding, laser welding, etc;

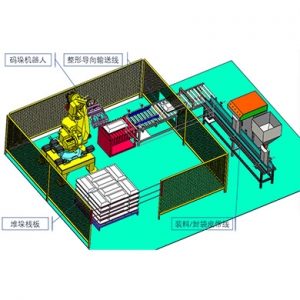

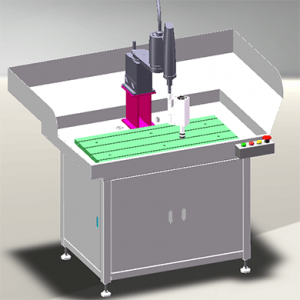

4. Worktable (linkage / non linkage): plane double / three station, rotary table, turnover table, access slide, etc;

5. Seventh axis (linkage / non linkage): imported and domestic rack guide rail;

6. Control mode: PLC + welding robot control system.

Product features:

1. Stabilize and improve the welding quality, and can reflect the welding quality in the form of numerical value;

2. Improve labor productivity;

3. Improve the labor intensity of workers and work in harmful environment;

4. Reduce the requirements for workers operation technology;

5. It shortens the preparation cycle of product upgrading and reduces the corresponding equipment investment.

Main configuration and performance:

1. Robot: OTC, Panasonic, KUKA, abb, FANUC, Yaskawa, six axis

2. Welding materials: aluminum, iron, stainless steel, etc;

3. Welding methods: gas shielded welding, argon arc welding, laser welding, etc;

4. Worktable (linkage / non linkage): plane double / three station, rotary table, turnover table, access slide, etc;

5. Seventh axis (linkage / non linkage): imported and domestic rack guide rail;

6. Control mode: PLC + welding robot control system.

Previous:Robot cutting workstation

Related articles

- Fan Cheng Tianji robot on duty: auxi···

- Fan Cheng Looking for Shenyang oppor···

- Detailed explanation of positioning ···

- Leaf vegetable factory starts automa···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng Focus on China and look ar···