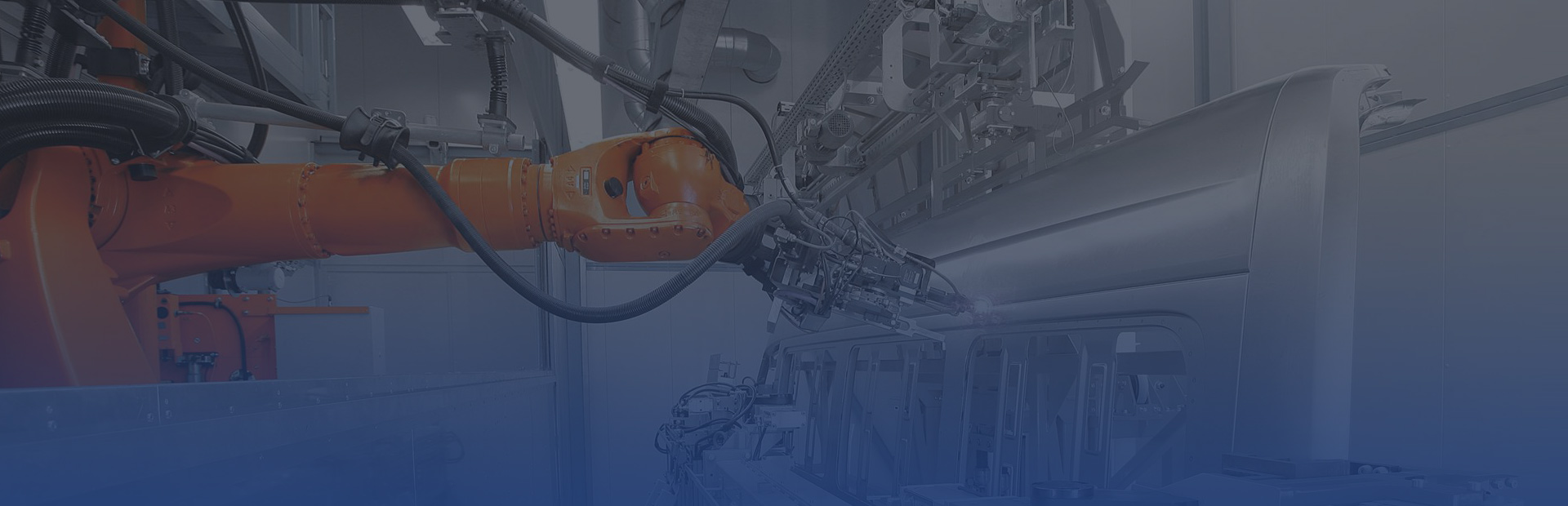

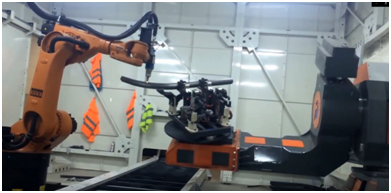

Robot cutting workstation

Consult Immediately

National hotline: +86 0769-85832096

Details

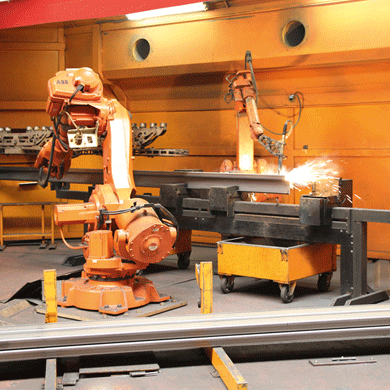

Robot cutting system changes the traditional cutting technology. It not only has flat incision and high accuracy, but also eliminates the subsequent grinding process. It is favored by the manufacturing industry. In actual production, robot cutting equipment has obvious advantages in improving product quality and production efficiency, shortening product development cycle, reducing labor intensity and saving raw materials. Although the equipment cost of the robot cutting system is high and the one-time investment is large, it is relatively affordable for long-term use. The production stability of the cutting robot is relatively strong, which can ensure the quality of products, save the cumbersome processes such as measurement and drawing before cutting, greatly improve the work efficiency, and play a more and more important role in the manufacturing industry. It is widely used in bus, truck, forklift, engineering machinery, agricultural machinery, fitness equipment, parts maintenance and other industries. It is mainly used in the cutting of automobile covering parts, including door, ceiling, side wall, engine cover, trunk cover, bumper, fender, etc. instead of manual plasma cutting, trimming die and punching die. In addition to metal materials, it can also cut soft shoes, acrylic crafts, plastic parts and other non-metallic materials.

Product features:

1. Cutting technology and industrial robot are highly integrated;

2. Flexible processing;

3. Three dimensional cutting, one-time forming;

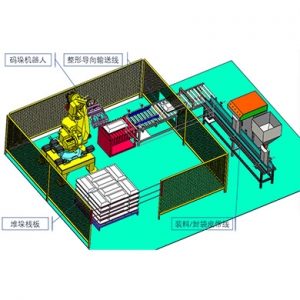

Main configuration and performance:

1. Robot: Yaskawa, FANUC, KUKA, abb, Staubli, six axis, 12kg-600kg

2. Cutting methods: plasma cutting, flame cutting, optical fiber laser cutting, vibrating knife cutting, etc;

3、 Control system: PLC + robot system;

4、 Worktable: plane type, rotary table, access slide, etc;

5、 Installation mode: front installation, side installation, upside down installation, gantry machine tool type, etc;

6、 Programming software: visual software, sprutcam, etc.

Product features:

1. Cutting technology and industrial robot are highly integrated;

2. Flexible processing;

3. Three dimensional cutting, one-time forming;

Main configuration and performance:

1. Robot: Yaskawa, FANUC, KUKA, abb, Staubli, six axis, 12kg-600kg

2. Cutting methods: plasma cutting, flame cutting, optical fiber laser cutting, vibrating knife cutting, etc;

3、 Control system: PLC + robot system;

4、 Worktable: plane type, rotary table, access slide, etc;

5、 Installation mode: front installation, side installation, upside down installation, gantry machine tool type, etc;

6、 Programming software: visual software, sprutcam, etc.

Previous:没有了!

Related articles

- Fan Cheng Tianji robot on duty: auxi···

- Fan Cheng Looking for Shenyang oppor···

- Detailed explanation of positioning ···

- Leaf vegetable factory starts automa···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng Focus on China and look ar···