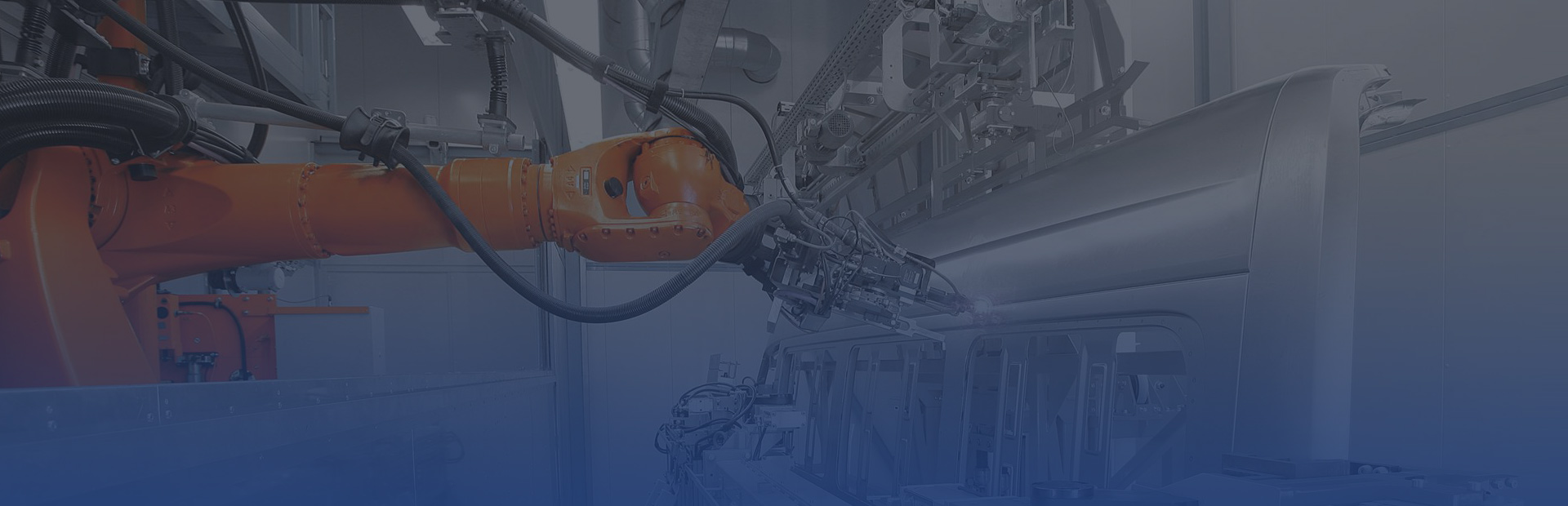

Robot bending workstation

Consult Immediately

National hotline: +86 0769-85832096

Details

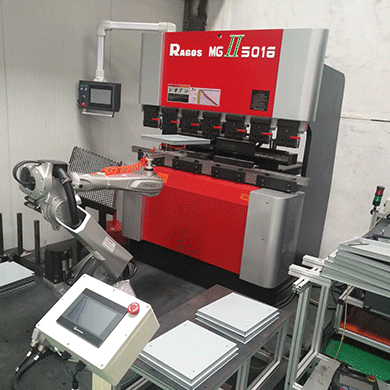

In the process of metal sheet metal bending, each bending machine needs to be equipped with an operator in traditional operation. Due to the wide variety and huge quantity of products required by all walks of life, and the bending machine belongs to the production equipment with high risk category, and the potential safety hazard is also relatively large. This production process has increasingly become a heavy and dangerous manual work, so using robots to replace human work has gradually become an inevitable development trend. In todays manufacturing industry, sheet metal bending has penetrated into many industries, such as automobile, household appliances, electrical, kitchenware, electronics and consumer goods.

Product features:

4. In the past, 2 ~ 3 bending workers were required to cooperate with the operation of large sheet metal workpieces. After using the bending robot, personnel operation can be reduced, cost can be reduced, labor can be replaced and safety accidents can be reduced;

5. The process can be recycled and mass produced, without process problems such as wrong and missing workpieces, wrong knife and re knife, and effectively reduce the scrap rate and repair rate;

6. It can work 24 hours without interruption, and can get high-quality flying from output and quality;

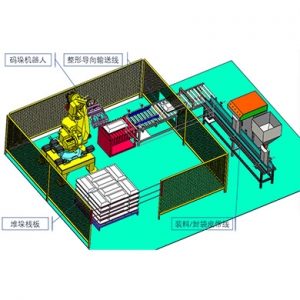

Main configuration and performance:

7. Robot: Yaskawa, FANUC, KUKA, abb, Kawasaki, esten, six axis, 50kg-600kg

8. Bending software package: SmartRobot bending, k-bending, etc;

9. Standard configuration: rear block refers to automatic alignment system, gripper system, centering system, feeding system, blanking system, turnover system, safety protection system and control system;

10. Optional: Seventh axis, magnetic separation;

11. Limitations: the product specifications are not fixed, the output is too small and unstable, and the bending machine needs to be replaced and adjusted frequently, resulting in the change of the reference position.

Product features:

4. In the past, 2 ~ 3 bending workers were required to cooperate with the operation of large sheet metal workpieces. After using the bending robot, personnel operation can be reduced, cost can be reduced, labor can be replaced and safety accidents can be reduced;

5. The process can be recycled and mass produced, without process problems such as wrong and missing workpieces, wrong knife and re knife, and effectively reduce the scrap rate and repair rate;

6. It can work 24 hours without interruption, and can get high-quality flying from output and quality;

Main configuration and performance:

7. Robot: Yaskawa, FANUC, KUKA, abb, Kawasaki, esten, six axis, 50kg-600kg

8. Bending software package: SmartRobot bending, k-bending, etc;

9. Standard configuration: rear block refers to automatic alignment system, gripper system, centering system, feeding system, blanking system, turnover system, safety protection system and control system;

10. Optional: Seventh axis, magnetic separation;

11. Limitations: the product specifications are not fixed, the output is too small and unstable, and the bending machine needs to be replaced and adjusted frequently, resulting in the change of the reference position.

Previous:Robot welding workstation

Related articles

- Fan Cheng Tianji robot on duty: auxi···

- Fan Cheng Looking for Shenyang oppor···

- Detailed explanation of positioning ···

- Leaf vegetable factory starts automa···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng [evert] innovative empower···

- Fan Cheng Focus on China and look ar···