Fan Cheng Youao robot discusses how to maintain business continuity in times of economic uncerta

Published on:2020-07-21

To survive in the highly competitive manufacturing industry, we must be able to adapt to the changing needs of customers and the changing global economic trend. Now the manufacturing industry is facing great challenges. There are still cities in the world in a period of forced factory closures and regional closures, and manufacturers have to stop operation. Of course, some manufacturers go against the trend and deploy or strengthen automated processes to maintain business continuity.

Traditional automation is costly and inflexible, requiring months or even years to design, develop and deploy. Minor modifications may need to stop operation for several weeks. In addition, traditional automation needs to occupy a lot of space, and can not meet the needs of man-machine safety cooperation. For manufacturers who need low cost, flexible deployment and minimal interference, deploying traditional automation systems is too expensive, difficult and time-consuming. Manufacturers who urgently need to transform their existing production lines focus on cooperative robots.

Fine tune the layout and adjust the production line in time

Spanish carmaker SIAT seat has been actively promoting intelligent production. In order to meet the current market demand, seat began to produce respirators. After deploying the ur10 cooperative robot of youao robot, the new assembly line can manufacture 300 ventilators per day. Ur10 cooperative robot mainly performs quality inspection tasks in the assembly line, which is significantly improved in consistency and accuracy compared with manual. Moreover, the ur10 cooperative robot is easy to integrate into the new assembly line, without major rectification of the existing pattern, and can quickly respond to the market demand.

In addition to medical equipment, the current market demand for online shopping is also surging to reduce exposure. DCL logistics is a distribution center located in Silicon Valley in the United States. With more and more customers turning to online shopping, e-commerce has increased significantly. The company has deployed a second ur10 cooperative robot on the expanded conveyor system to meet the recent large-scale growth of online shopping demand.

Accurate detection and consolidation of customer relationship

Adjust the production line to manufacture new products. Speed is one aspect, and quality is more important. Therefore, quality inspection is essential to ensure product quality in order to live up to the trust of customers.

Youao robot has mature applications in the field of quality inspection.

Japans Koyo electronics industries (Guangyang Electronics Industry Co., Ltd.) arranged UR3 cooperative robot in the post of touch screen quality inspection, which solved the problem of manpower shortage and increased productivity by 31%. UR3 cooperative robot touches the screen with a stylus. When "OK" is displayed, the green light is on and the product passes; Display "ng", the red light is on, and there is a continuous prompt tone, so that the staff can find out and take further measures at the first time.

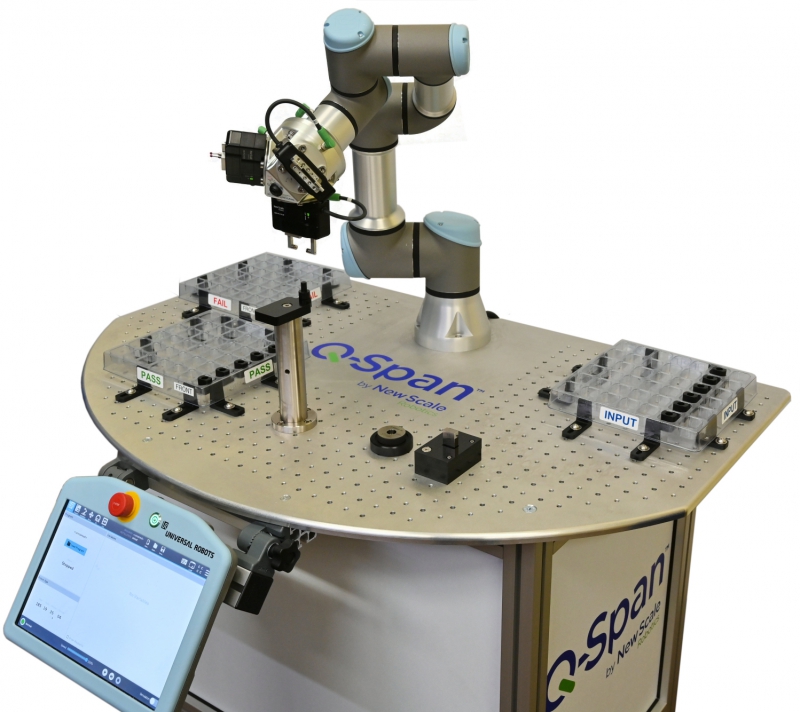

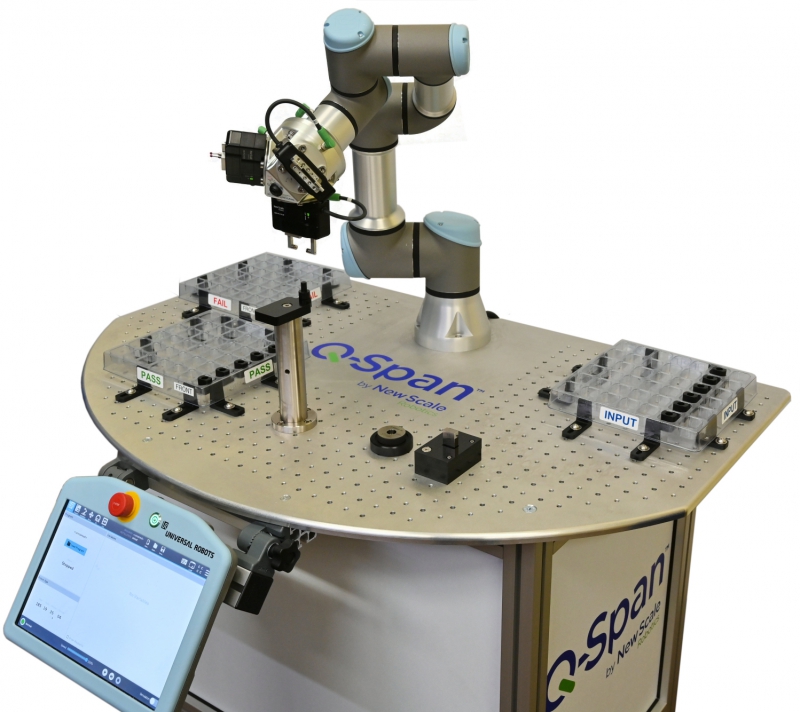

In addition, youao robot has developed corresponding solutions in close cooperation with ur + * partners. Moreover, the new "plug and play" Application Suite launched by ur + platform recently can reduce the repetitive technical evaluation of common applications, not only reduce the project risk and complexity, but also realize rapid deployment and complete quality inspection and other tasks. The q-span workstation suite jointly developed with new scale robotics can be used for QC measurement inspection, automatic digital caliper measurement and data recording, improve the consistency and repeatability of small part measurement, and eliminate data input errors.

Flexibility is one of the important driving forces for the rapid development of cooperative robots in the world. In 2018, cooperative robots accounted for only 3% of the global robot expenditure, but it was the fastest growing part in the field of industrial robots; By 2025, cooperative robots are expected to leap from the minority to the mainstream, accounting for 34% of the global robot expenditure. When manufacturers face various uncertainties, cooperative robots provide effective solutions to maintain business continuity and innovation, and prepare for future challenges.

Traditional automation is costly and inflexible, requiring months or even years to design, develop and deploy. Minor modifications may need to stop operation for several weeks. In addition, traditional automation needs to occupy a lot of space, and can not meet the needs of man-machine safety cooperation. For manufacturers who need low cost, flexible deployment and minimal interference, deploying traditional automation systems is too expensive, difficult and time-consuming. Manufacturers who urgently need to transform their existing production lines focus on cooperative robots.

Fine tune the layout and adjust the production line in time

Spanish carmaker SIAT seat has been actively promoting intelligent production. In order to meet the current market demand, seat began to produce respirators. After deploying the ur10 cooperative robot of youao robot, the new assembly line can manufacture 300 ventilators per day. Ur10 cooperative robot mainly performs quality inspection tasks in the assembly line, which is significantly improved in consistency and accuracy compared with manual. Moreover, the ur10 cooperative robot is easy to integrate into the new assembly line, without major rectification of the existing pattern, and can quickly respond to the market demand.

In addition to medical equipment, the current market demand for online shopping is also surging to reduce exposure. DCL logistics is a distribution center located in Silicon Valley in the United States. With more and more customers turning to online shopping, e-commerce has increased significantly. The company has deployed a second ur10 cooperative robot on the expanded conveyor system to meet the recent large-scale growth of online shopping demand.

Accurate detection and consolidation of customer relationship

Adjust the production line to manufacture new products. Speed is one aspect, and quality is more important. Therefore, quality inspection is essential to ensure product quality in order to live up to the trust of customers.

Youao robot has mature applications in the field of quality inspection.

Japans Koyo electronics industries (Guangyang Electronics Industry Co., Ltd.) arranged UR3 cooperative robot in the post of touch screen quality inspection, which solved the problem of manpower shortage and increased productivity by 31%. UR3 cooperative robot touches the screen with a stylus. When "OK" is displayed, the green light is on and the product passes; Display "ng", the red light is on, and there is a continuous prompt tone, so that the staff can find out and take further measures at the first time.

In addition, youao robot has developed corresponding solutions in close cooperation with ur + * partners. Moreover, the new "plug and play" Application Suite launched by ur + platform recently can reduce the repetitive technical evaluation of common applications, not only reduce the project risk and complexity, but also realize rapid deployment and complete quality inspection and other tasks. The q-span workstation suite jointly developed with new scale robotics can be used for QC measurement inspection, automatic digital caliper measurement and data recording, improve the consistency and repeatability of small part measurement, and eliminate data input errors.

Flexibility is one of the important driving forces for the rapid development of cooperative robots in the world. In 2018, cooperative robots accounted for only 3% of the global robot expenditure, but it was the fastest growing part in the field of industrial robots; By 2025, cooperative robots are expected to leap from the minority to the mainstream, accounting for 34% of the global robot expenditure. When manufacturers face various uncertainties, cooperative robots provide effective solutions to maintain business continuity and innovation, and prepare for future challenges.