Fan Cheng In the era of industrial intelligence, there is no place to place data

Published on:2020-07-29

In industry 4Driven by the strategies of. 0 and intelligent manufacturing, new generation information technologies such as Internet of things, 5g, cloud computing and artificial intelligence are accelerating the integration with traditional industries. More and more enterprises rely on the Internet of things to connect people, machines and things and collect data. At the same time, with the help of 5g, cloud computing, artificial intelligence and other technologies for data transmission, aggregation, calculation and analysis, the landing of industrial intelligence scene has led to a sharp increase in the amount of data, which also brings great challenges to the transformation and upgrading of enterprises.

Industry enters the era of data flood

In the past 30 years, enterprises have used CAX, PLM, ERP, OA and other information-based software to solve many needs in the process of product R & D and operation management, as well as MES and APS to partially solve the needs in the process of production management, such as production resource management and scheduling. However, if they want to go further to the industrial site and manage and control machines and equipment, they are powerless.

As the Internet of things, 5g, artificial intelligence and other new generation information technologies gradually mature and integrate into traditional industrial production, the unsolved problems in the information age are being broken through one by one. Enterprises use the Internet of things to connect people, machines and things on the industrial site, and use the edge computing platform to collect, aggregate and analyze the data of key equipment, so as to realize the data connection with the upper business system, and realize the data sharing and interaction through cloud edge collaboration, so as to form a complete closed-loop industrial chain covering R & D, operation, production and sales, This has also become the basis for the realization of digitization and intelligence.

From informatization to intelligence, the author summarizes two changes: one is the transformation of objects from "people" to "things", and the other is the transfer of scenes from "office area" to "production area". Informatization solves the problem of behavior management of "people". Intellectualization solves the problem of "object" operation control. The problems that can be solved by one computer in the past must be added with industrial systems and automation equipment. The difference between it and OT in the standard architecture makes the integration of the two complex and difficult.

When the business boundary extends downward, it also brings greater problems, that is, the data obtained by enterprises is not as regular as before, there are more and more unstructured data, the generation frequency is higher, and many data need to be obtained and analyzed in time. Whats more troublesome is that industrial processes produce far more data than ever before.

IDC predicts that by 2025, the amount of real-time data of equipment will be 200 times that of 2017, reaching an amazing 49zb. With the development of industrial intelligence, the proportion of unstructured data will be higher and higher. For enterprises, the industrial data generated all the time is under great pressure from storage management and database, which has become a priority problem to be solved in the intelligent transformation of enterprises.

Traditional databases are no longer competent

Ten years ago, when I was still working as a programmer, whenever there was a new demand, the first thing to do was to evaluate what development language and database to use? At that time, Oracle, MySQL and SQL Server were used most. These relational databases can provide functional interaction services for users, which are suitable for structured data stored in SQL index tables with low data generation frequency.

When we enter the intelligent era and face the needs of app development in more and more industrial scenes, can we still use the traditional relational database? The answer is obviously not. There are three main reasons:

First, the data structure is different. In the information age, a computer dominates the world. All software products are built on the general operating system and standardized hardware architecture. Software applications can run only if they meet the x86 + windows platform standard, and the data generated are structured data. However, there is no unified operating system and system standard in the industrial scene. Heterogeneous industrial systems and equipment will produce many different forms of data, mostly unstructured, which can not be supported by the traditional relational database.

Second, most industrial fields are business scenarios with high real-time performance. Downtime is allowed in the operation process of traditional information systems, but not in industrial scenarios. Especially in the process industry, the generation process is continuous, and the data collection is also time-series data. Any interruption may produce huge security risks. With more and more access devices, enterprises need to collect and process more and more real-time and time-series data, which needs to be able to manage a large number of real-time professional databases of devices, which can not be done by traditional relational databases.

Third, in the process of promoting industrial intelligence, it is necessary to manage, store and analyze massive industrial data. Aggregating and classifying a large number of different types of industrial data is the basic premise of realizing intelligent analysis. Traditional relational databases have poor performance in data aggregation analysis. The compression of timing data is relatively low, and needs to occupy a lot of machine resources.

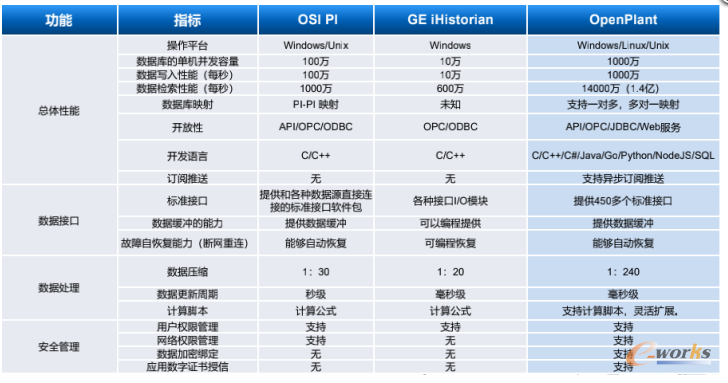

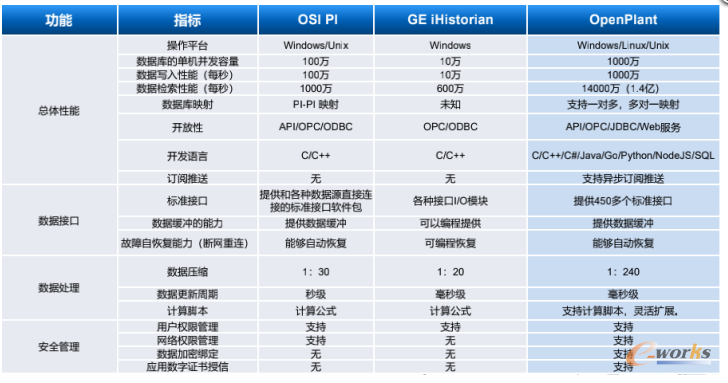

At present, leading industrial database enterprises not only have professional compression algorithms, but also fully consider the aggregation performance of massive data real-time analysis. Openplant database launched by domestic maijie technology has a special real-time data compression algorithm, which is 90% lower than the traditional relational database. Through the optimization of writing, storage, query and other processes, the performance of real-time database can reach more than 1000 times that of traditional data.

Be the leader of real-time database

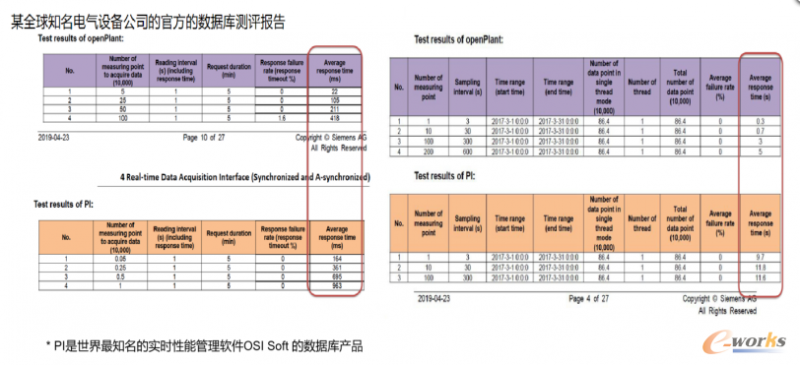

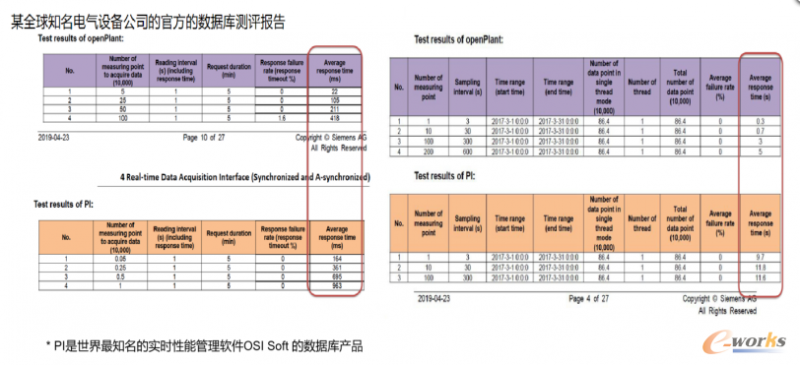

In 2019, a customer test example of openplant and PI was provided in the official database evaluation report of a world-famous electrical equipment company. The former is the domestic real-time database company majecTechnology is the main database for industrial Internet platform applications, which is the database product of OSI soft, the worlds most famous real-time performance management software.

In the thread test for real-time data retrieval, openplant reads 2.4 million test points per second, while PI reads 10000 test points per second. In the thread test for historical data analysis and retrieval, openplant realizes the reading of 2.8 million records per second, while PI reads 90000 records per second. The test results show that the average response time of openplant reading and writing is much lower than that of PI, which shows that openplant database has higher concurrent reading and writing performance. As a completely self created domestic real-time database product, it has surpassed the top foreign products. How does Maggie technology do it?

Founded in 2000, maijie technology is an enterprise focusing on the research and application of industrial real-time data management technology. Openplant real-time database products integrate the R & D achievements of maijie technology in the industrial field for many years. Openplant real-time database can surpass foreign top products, mainly due to many years of industrial real-time data management technology research and industrial experience, so that Maggie technology can deeply understand the pain points and needs of enterprises, and continuously optimize and improve in combination with problems.

Openplant real-time database performance the worlds leading three core technologies include: intelligent data compression technology, database capacity, stand-alone performance and unique data transmission technology.

Firstly, the intelligent data compression technology of Maggie technology can make the storage compression ratio reach more than 200. The three modes of lossless compression, lossy compression and intelligent compression can be independently selected according to the needs of users, so as to optimize the data storage space on the premise of effectively ensuring the data accuracy.

Secondly, the single machine capacity of openplant real-time database can reach tens of millions, and supports distributed unlimited capacity expansion. The collection frequency is synchronized with the data source. The single machine real-time processing performance can reach 10 million events / s, and the access time of 1 million data points is less than 400 milliseconds. It supports concurrent access of more than 2000 users.

Third, the unique data transmission technology can not only track, verify and reissue the real-time transmitted data in the complex network environment, ensure the integrity and effectiveness of the data, and provide a strong guarantee for the accuracy of data analysis. At the same time, it can realize more than 10 times of data compression in the transmission process, helping enterprises save more than 90% of traffic costs, Reduce application costs.

In order to ensure the high reliability, high availability and multi platform support ability of the use process, openplant real-time database supports single machine, dual machine, distributed, HA and other deployment modes, as well as the data cross mapping function to meet a variety of disaster recovery application scenarios. Openplant real-time database provides complete information security strategy, customer-defined encryption strategy and professional technology encryption method, which runs through the whole process of data collection, transmission and access, and has passed the data security certification of the Ministry of public security.

With Chinas industrial upgrading and transformation entering a critical period, developed industrial countries began to gradually tighten the control over the use of industrial software by Chinese enterprises, and the development of independent industrial software has become a top priority. As the core basic software of industrial software, the database with high concurrency and massive data management has been monopolized by foreign high-end products for a long time, forming a potential industrial risk point for the smooth promotion of Chinas intelligent manufacturing.

As the leader of domestic real-time / time series database software, its openplant real-time database not only catches up with and greatly surpasses foreign high-end products, but also supports UNIX, Linux, windows and other mainstream operating systems under traditional and virtualized architecture in order to cooperate with the continuous national production process of industrial software, And fully support domestic chips and domestic operating systems to build the most solid "firewall" for the intelligent upgrading of Chinese enterprises.

In addition, in the face of the rapid development process of industrial Internet, with the experience of providing data acquisition, storage and data analysis for more than 80 million devices, Majie technology has built and developed an integrated platform of Internet of things based on openplant real-time database and relying on its own industrial big data management technology, cloud computing, edge computing and other technologies accumulated for many years. Eliminate the pain points of industrial Internet application from five levels: data access layer, transmission aggregation layer, storage processing layer, business analysis layer and value realization layer, help enterprises reduce hardware investment by at least 60%, and greatly shorten the development cycle and construction cost, greatly reduce the later operation and maintenance cost.

Industry enters the era of data flood

In the past 30 years, enterprises have used CAX, PLM, ERP, OA and other information-based software to solve many needs in the process of product R & D and operation management, as well as MES and APS to partially solve the needs in the process of production management, such as production resource management and scheduling. However, if they want to go further to the industrial site and manage and control machines and equipment, they are powerless.

As the Internet of things, 5g, artificial intelligence and other new generation information technologies gradually mature and integrate into traditional industrial production, the unsolved problems in the information age are being broken through one by one. Enterprises use the Internet of things to connect people, machines and things on the industrial site, and use the edge computing platform to collect, aggregate and analyze the data of key equipment, so as to realize the data connection with the upper business system, and realize the data sharing and interaction through cloud edge collaboration, so as to form a complete closed-loop industrial chain covering R & D, operation, production and sales, This has also become the basis for the realization of digitization and intelligence.

From informatization to intelligence, the author summarizes two changes: one is the transformation of objects from "people" to "things", and the other is the transfer of scenes from "office area" to "production area". Informatization solves the problem of behavior management of "people". Intellectualization solves the problem of "object" operation control. The problems that can be solved by one computer in the past must be added with industrial systems and automation equipment. The difference between it and OT in the standard architecture makes the integration of the two complex and difficult.

When the business boundary extends downward, it also brings greater problems, that is, the data obtained by enterprises is not as regular as before, there are more and more unstructured data, the generation frequency is higher, and many data need to be obtained and analyzed in time. Whats more troublesome is that industrial processes produce far more data than ever before.

IDC predicts that by 2025, the amount of real-time data of equipment will be 200 times that of 2017, reaching an amazing 49zb. With the development of industrial intelligence, the proportion of unstructured data will be higher and higher. For enterprises, the industrial data generated all the time is under great pressure from storage management and database, which has become a priority problem to be solved in the intelligent transformation of enterprises.

Traditional databases are no longer competent

Ten years ago, when I was still working as a programmer, whenever there was a new demand, the first thing to do was to evaluate what development language and database to use? At that time, Oracle, MySQL and SQL Server were used most. These relational databases can provide functional interaction services for users, which are suitable for structured data stored in SQL index tables with low data generation frequency.

When we enter the intelligent era and face the needs of app development in more and more industrial scenes, can we still use the traditional relational database? The answer is obviously not. There are three main reasons:

First, the data structure is different. In the information age, a computer dominates the world. All software products are built on the general operating system and standardized hardware architecture. Software applications can run only if they meet the x86 + windows platform standard, and the data generated are structured data. However, there is no unified operating system and system standard in the industrial scene. Heterogeneous industrial systems and equipment will produce many different forms of data, mostly unstructured, which can not be supported by the traditional relational database.

Second, most industrial fields are business scenarios with high real-time performance. Downtime is allowed in the operation process of traditional information systems, but not in industrial scenarios. Especially in the process industry, the generation process is continuous, and the data collection is also time-series data. Any interruption may produce huge security risks. With more and more access devices, enterprises need to collect and process more and more real-time and time-series data, which needs to be able to manage a large number of real-time professional databases of devices, which can not be done by traditional relational databases.

Third, in the process of promoting industrial intelligence, it is necessary to manage, store and analyze massive industrial data. Aggregating and classifying a large number of different types of industrial data is the basic premise of realizing intelligent analysis. Traditional relational databases have poor performance in data aggregation analysis. The compression of timing data is relatively low, and needs to occupy a lot of machine resources.

At present, leading industrial database enterprises not only have professional compression algorithms, but also fully consider the aggregation performance of massive data real-time analysis. Openplant database launched by domestic maijie technology has a special real-time data compression algorithm, which is 90% lower than the traditional relational database. Through the optimization of writing, storage, query and other processes, the performance of real-time database can reach more than 1000 times that of traditional data.

Be the leader of real-time database

In 2019, a customer test example of openplant and PI was provided in the official database evaluation report of a world-famous electrical equipment company. The former is the domestic real-time database company majecTechnology is the main database for industrial Internet platform applications, which is the database product of OSI soft, the worlds most famous real-time performance management software.

In the thread test for real-time data retrieval, openplant reads 2.4 million test points per second, while PI reads 10000 test points per second. In the thread test for historical data analysis and retrieval, openplant realizes the reading of 2.8 million records per second, while PI reads 90000 records per second. The test results show that the average response time of openplant reading and writing is much lower than that of PI, which shows that openplant database has higher concurrent reading and writing performance. As a completely self created domestic real-time database product, it has surpassed the top foreign products. How does Maggie technology do it?

Founded in 2000, maijie technology is an enterprise focusing on the research and application of industrial real-time data management technology. Openplant real-time database products integrate the R & D achievements of maijie technology in the industrial field for many years. Openplant real-time database can surpass foreign top products, mainly due to many years of industrial real-time data management technology research and industrial experience, so that Maggie technology can deeply understand the pain points and needs of enterprises, and continuously optimize and improve in combination with problems.

Openplant real-time database performance the worlds leading three core technologies include: intelligent data compression technology, database capacity, stand-alone performance and unique data transmission technology.

Firstly, the intelligent data compression technology of Maggie technology can make the storage compression ratio reach more than 200. The three modes of lossless compression, lossy compression and intelligent compression can be independently selected according to the needs of users, so as to optimize the data storage space on the premise of effectively ensuring the data accuracy.

Secondly, the single machine capacity of openplant real-time database can reach tens of millions, and supports distributed unlimited capacity expansion. The collection frequency is synchronized with the data source. The single machine real-time processing performance can reach 10 million events / s, and the access time of 1 million data points is less than 400 milliseconds. It supports concurrent access of more than 2000 users.

Third, the unique data transmission technology can not only track, verify and reissue the real-time transmitted data in the complex network environment, ensure the integrity and effectiveness of the data, and provide a strong guarantee for the accuracy of data analysis. At the same time, it can realize more than 10 times of data compression in the transmission process, helping enterprises save more than 90% of traffic costs, Reduce application costs.

In order to ensure the high reliability, high availability and multi platform support ability of the use process, openplant real-time database supports single machine, dual machine, distributed, HA and other deployment modes, as well as the data cross mapping function to meet a variety of disaster recovery application scenarios. Openplant real-time database provides complete information security strategy, customer-defined encryption strategy and professional technology encryption method, which runs through the whole process of data collection, transmission and access, and has passed the data security certification of the Ministry of public security.

With Chinas industrial upgrading and transformation entering a critical period, developed industrial countries began to gradually tighten the control over the use of industrial software by Chinese enterprises, and the development of independent industrial software has become a top priority. As the core basic software of industrial software, the database with high concurrency and massive data management has been monopolized by foreign high-end products for a long time, forming a potential industrial risk point for the smooth promotion of Chinas intelligent manufacturing.

As the leader of domestic real-time / time series database software, its openplant real-time database not only catches up with and greatly surpasses foreign high-end products, but also supports UNIX, Linux, windows and other mainstream operating systems under traditional and virtualized architecture in order to cooperate with the continuous national production process of industrial software, And fully support domestic chips and domestic operating systems to build the most solid "firewall" for the intelligent upgrading of Chinese enterprises.

In addition, in the face of the rapid development process of industrial Internet, with the experience of providing data acquisition, storage and data analysis for more than 80 million devices, Majie technology has built and developed an integrated platform of Internet of things based on openplant real-time database and relying on its own industrial big data management technology, cloud computing, edge computing and other technologies accumulated for many years. Eliminate the pain points of industrial Internet application from five levels: data access layer, transmission aggregation layer, storage processing layer, business analysis layer and value realization layer, help enterprises reduce hardware investment by at least 60%, and greatly shorten the development cycle and construction cost, greatly reduce the later operation and maintenance cost.