Fan Cheng dried food! Full of dry goods! Nanoscan3 for slam evaluation

Published on:2020-04-26

Today, Id like to share an assessment of the high content of dry goods. The two protagonists are: Xianzhi SRC series core controller and sicks latest safety lidar nanoscan3.

Nanoscan3 is a laser radar newly adapted to Xianzhi SRC series core controller. How about this nanoscan3 laser radar? Xianzhi asked a technical master to test it professionally.

In this issue of dry goods sharing, we will introduce in detail how to connect nanoscan3 to Xianzhi src-2000 (s) controller and complete slam application test.

[I. product configuration]

The step of configuring the safety designer of nanoscan3 product is well known, and 100 words are omitted here.

[2 access to Xianzhi SRC series core controller]

SRC series core controller is a general controller designed for mobile robots (AGV, AMR, automatic forklift, etc.), which provides the core functions of map construction, positioning and navigation, model editing and so on.

The controller is suitable for many mainstream lidar and provides rich I / O, can, RS485 and other interfaces for accessing various sensors and driver devices.

Configure the laser equipment accessed by SRC through the roboshop Pro client software of Xianzhi one-stop implementation tool, as shown in the following figure:

The scanning range of nanoscan3 is 275 °, so the left and right scanning angle range can be configured as [- 137.5 °, 137.5 °], and the angle resolution step is 0.17 °.

【 III slam application test 】

Here comes the key content of dry goods!

01 slam drawing effect

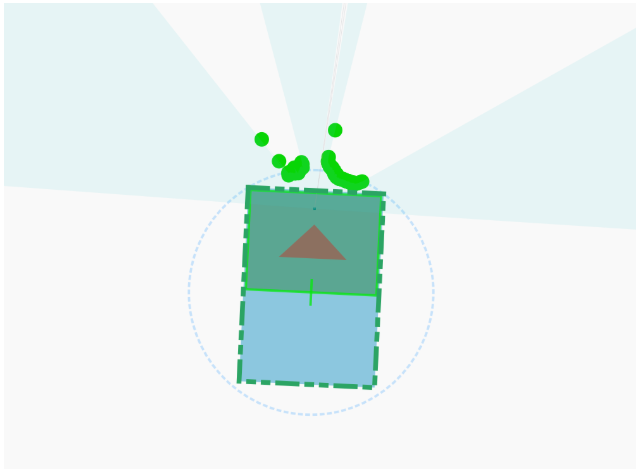

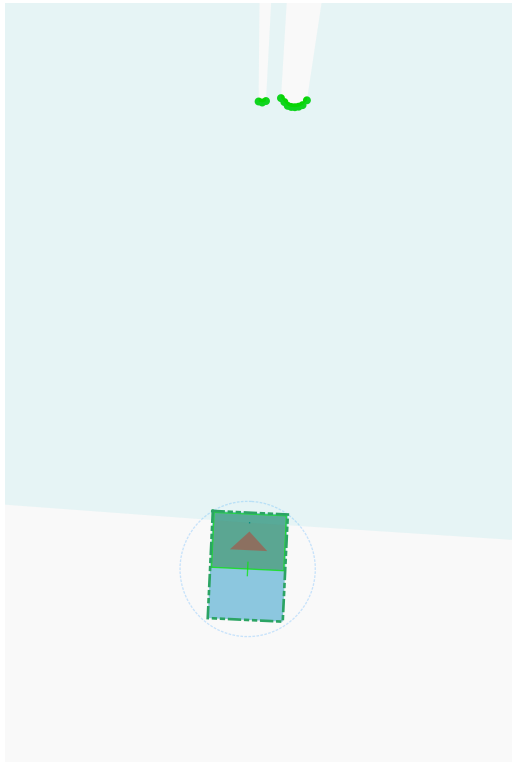

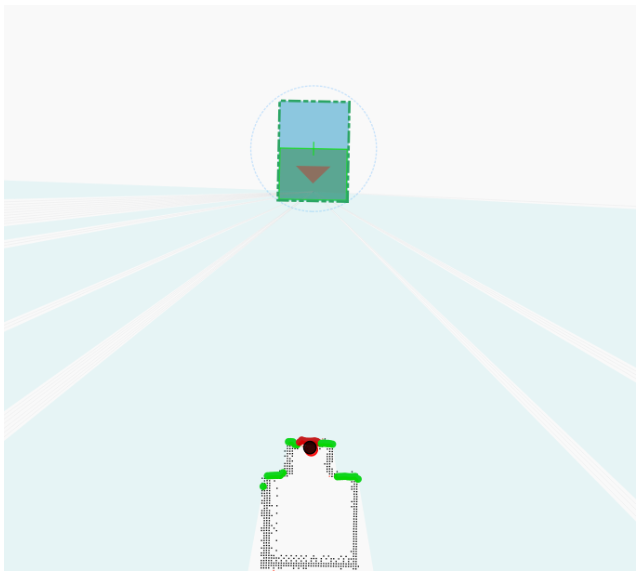

After the access of nanoscan3 is completed, slam mapping can be started. We adopt the conventional mapping method, that is, we make a circle around the site environment to form a closed loop. The process is as follows:

▲ slam mapping process ▲

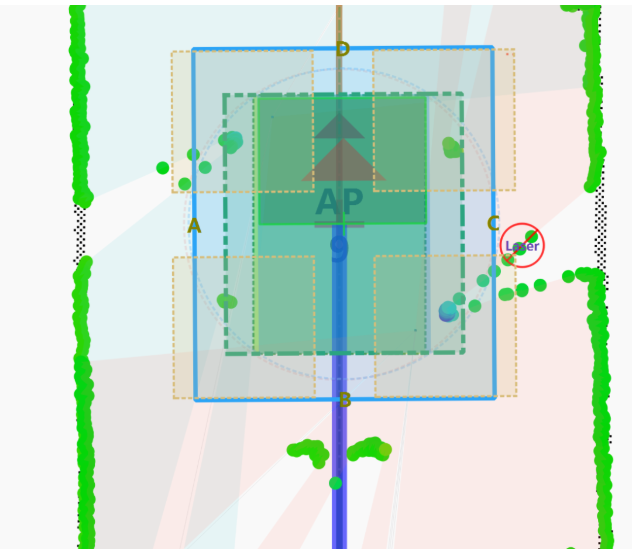

The running speed during drawing construction is 1m / s and the angular speed is 30 ° / s. The map obtained by simply erasing the dynamic objects in the map is as follows:

By zooming in, you can see that the map built with nanoscan3 has straight walls, thin thickness, and no ghosting.

▲ nanoscan3 build map effect ▲

02 actual effective distance test

The nominal maximum effective distance of nanoscan3 is 40m. In the actual test, the correct laser data feedback can be obviously obtained from the wall 40m away from the robot, as shown in the following figure:

03 ranging stability test

For the stability of ranging, we take three cases: long distance, medium distance and short distance.

Long distance (& gt; 30m)

It can be seen from the moving picture that nanoscan3 is excellent in long-distance ranging. The data jump is basically between two map points (about 2cm), and the performance is far superior to similar products.

Medium distance (about 10m)

The data jump of distance in nanoscan3 can be basically ignored (& lt; 1cm).

The accuracy of the data is mainly investigated at a short distance. If the laser processing is not good, it will lead to noise, so the shape of the object cannot be restored correctly. Here, an object with a right angle is used for testing.

Short distance (& lt; 0.1M)

It can be seen that nanoscan3 perfectly restores the shape of the object, does not deform the right angle due to laser noise, and the jump of data is very small.

04 detection of black objects

Nanoscan3 is a safety product. Its detection standard for black objects is very high. It can detect reflectivity of 1More than 0.8% of objects.

We tested using gray black cylinders with diameters of 70mm and 200mm respectively:

▲ the diameters are 70mm and 200mm respectively ▲

The laser is 10cm away from the cylinder

The laser is 3M away from the cylinder

It can be seen that the detection of gray and black objects at different distances by nanoscan3 is also very stable, which can better restore the shape of the object, and there is no case of invalid data points.

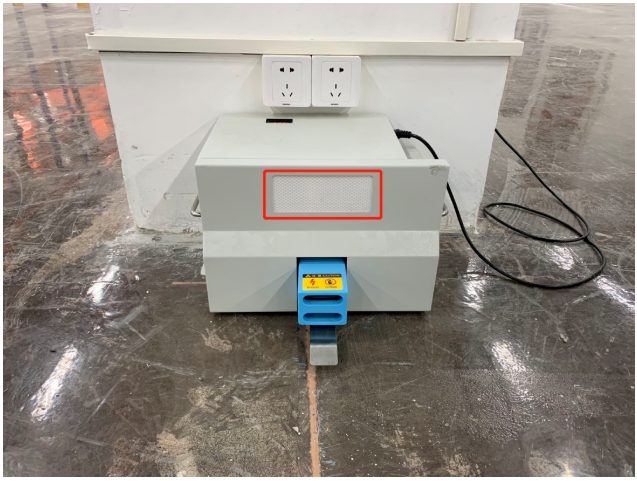

05 detection of reflectors

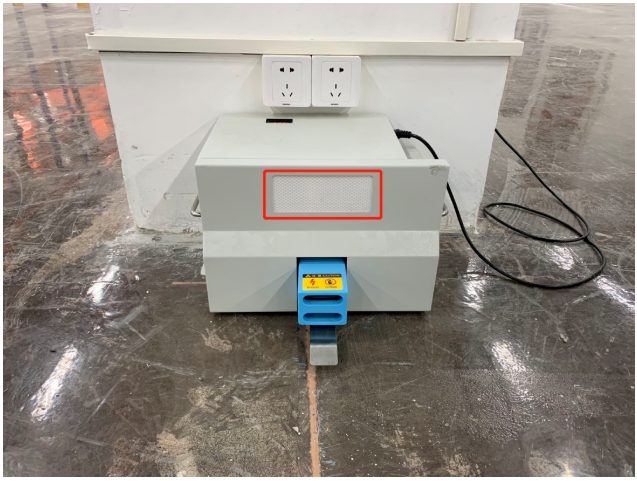

The reflective object test is conducted by using Xianzhi special charging pile to test whether the reflectivity obtained by nanoscan3 is stable at different distances. In the red box below is 3M reflective strip with a length of 18cm.

▲ inside the red frame: reflective strip with length of 18cm ▲

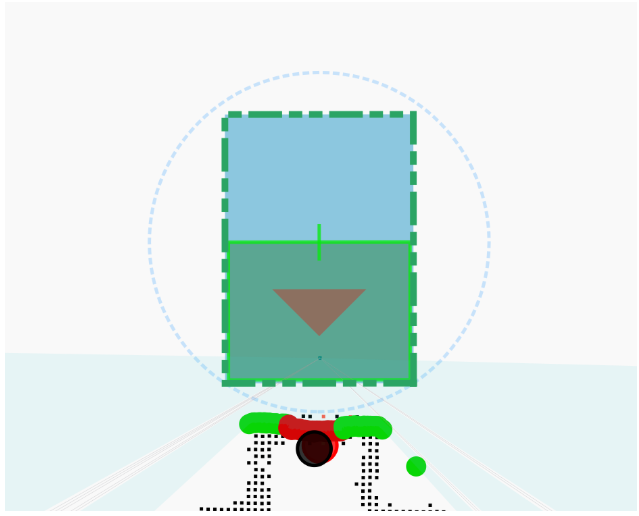

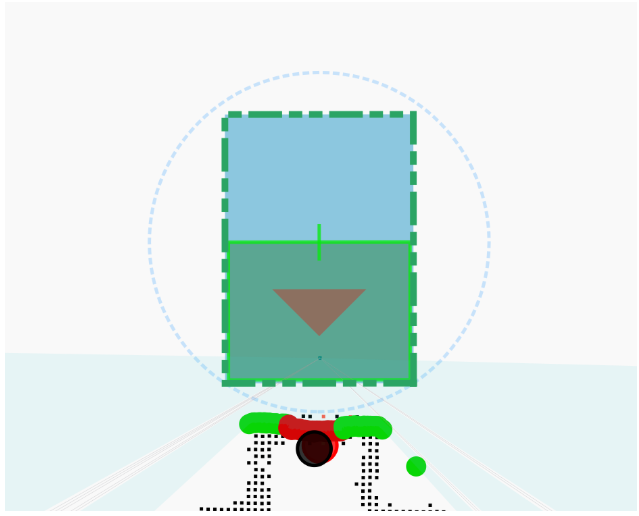

The laser is 10cm away from the reflective strip

In the above figure, the reflectivity of red laser spots is higher than that of green laser spots, which indicates that the laser has detected strip-shaped reflectors, and the reflectors are in a straight line without deformation and noise.

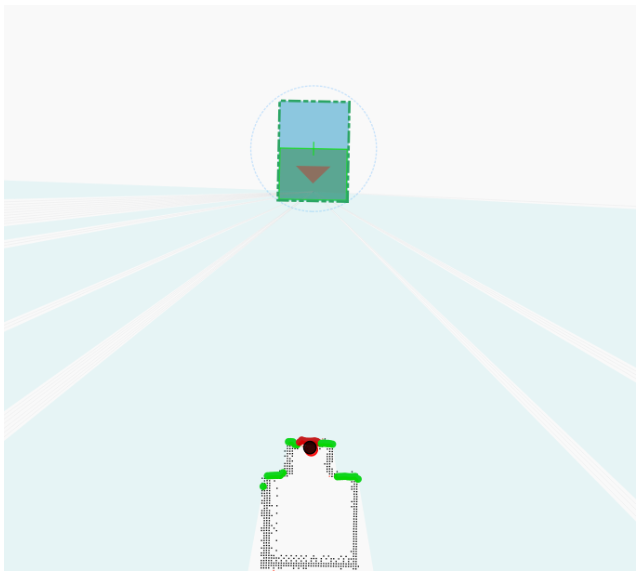

The laser is 2m away from the reflective strip

It can be seen that the strip reflector at 2m is still obvious, and the reflectivity in the laser data remains stable.

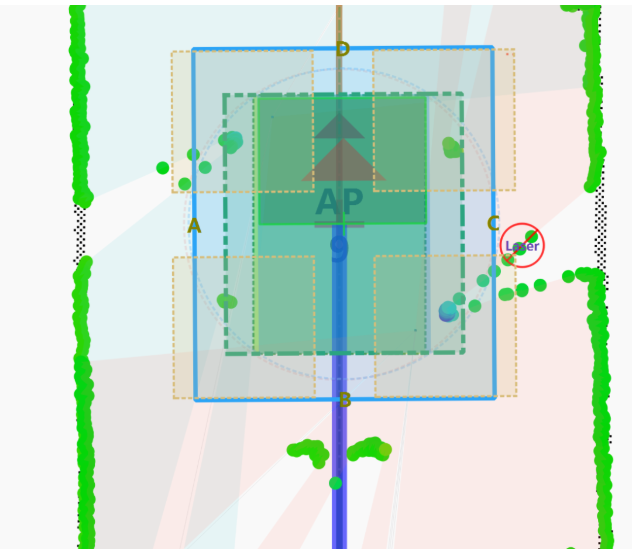

It can be seen that the stability of the reflectivity of nanoscan3 data is very excellent. There will be no instability of the reflectivity data at close range, which is significantly better than the same type of lidar on the market, which is very friendly to the relevant applications of identifying reflective objects.

In order to test the longest distance detected by the reflector, the 10cm diameter reflector in the figure below is used for testing:

▲ reflector with diameter of 10cm ▲

After testing, reflective columns with a diameter of 10cm can be stably detected within a range of about 20m (ensuring two high reflective points). The black points in the figure below are the detected reflective columns.

06 foreground noise test

As shown in the figure below, if there is a columnar object at the red dot, at this time, part of the beam that should have scanned the wall will be blocked by the columnar object. Because the laser beam is not a point, but a spot with size, half of the spot will hit the wall and the other half of the spot will hit the columnar object in front. In this case, the foreground noise of the laser is generated.

▲ generate laser foreground noise ▲

The following figure shows the serious foreground noise generated by other brands of lidar, which will directly affect the normal operation of the latent traction robot.

▲ testing of other brands ▲

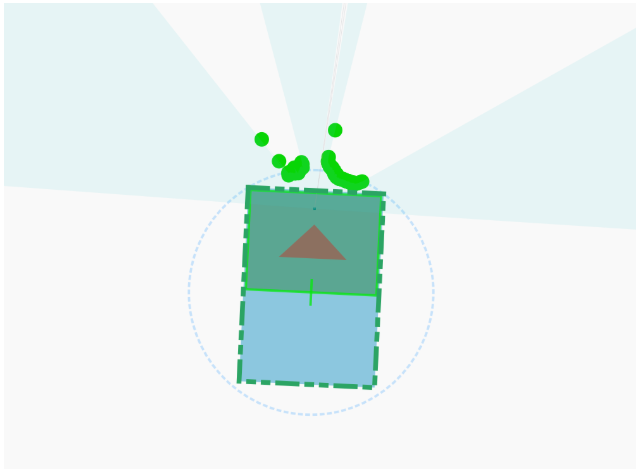

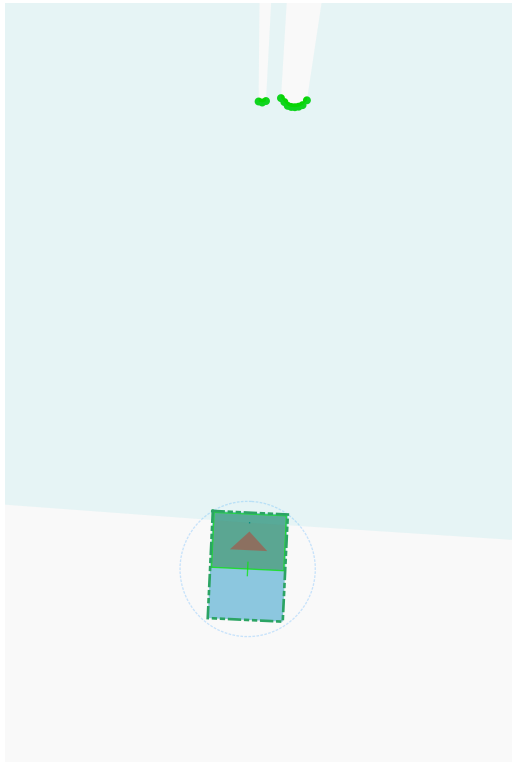

We simulated a similar situation and tested nanoscan3:

▲ nanoscan3 test ▲

As can be seen from the above dynamic diagram, although nanoscan3 produces foreground noise, there will only be one noise point in one direction, which has no great impact on practical applications. This, thanks to sicks safehddm? High precision measurement patented technology.

[IV. summary]

After in-depth testing, Xianzhi believes that the new product nanoscan3 of sick is a very excellent product, and its superior performance helps slam technology to be better applied to mobile robots. Moreover, nanoscan3 is a product that takes into account safety functions. Combined with the Flexi soft suite of sick and the src-2000 (s) controller of Xianzhi, it can quickly build a mobile robot product that meets the CE safety standard.

About Xianzhi

Xianzhi robot is a high-tech enterprise with mobile robot control and scheduling as the core. As a one-stop mobile robot scheme expert, Xianzhi robot has mastered the core technology of mobile robot with independent intellectual property rights, and has rich project experience in the field of industrial automation. Xianzhi robot is committed to serving industry integrators and providing them with one-stop mobile robot solutions including mobile robot control, scheduling and information management.

At present, the products, technologies and solutions of Xianzhi robot have been widely used in automobile manufacturing, home appliance manufacturing, 3C electronic manufacturing, semiconductor manufacturing, food and tobacco, e-commerce storage, security inspection, commercial services, medical education and other fields.

Xianzhi robot actively implements its corporate mission - "let intelligence create value", constantly adheres to technological innovation, and works with partners in an open, inclusive and win-win attitude, so as to meet customers high-quality pursuit of products, technologies and solutions to the greatest extent, and strive to "become an innovator and leader in the robot industry!"

Nanoscan3 is a laser radar newly adapted to Xianzhi SRC series core controller. How about this nanoscan3 laser radar? Xianzhi asked a technical master to test it professionally.

In this issue of dry goods sharing, we will introduce in detail how to connect nanoscan3 to Xianzhi src-2000 (s) controller and complete slam application test.

[I. product configuration]

The step of configuring the safety designer of nanoscan3 product is well known, and 100 words are omitted here.

[2 access to Xianzhi SRC series core controller]

SRC series core controller is a general controller designed for mobile robots (AGV, AMR, automatic forklift, etc.), which provides the core functions of map construction, positioning and navigation, model editing and so on.

The controller is suitable for many mainstream lidar and provides rich I / O, can, RS485 and other interfaces for accessing various sensors and driver devices.

Configure the laser equipment accessed by SRC through the roboshop Pro client software of Xianzhi one-stop implementation tool, as shown in the following figure:

The scanning range of nanoscan3 is 275 °, so the left and right scanning angle range can be configured as [- 137.5 °, 137.5 °], and the angle resolution step is 0.17 °.

【 III slam application test 】

Here comes the key content of dry goods!

01 slam drawing effect

After the access of nanoscan3 is completed, slam mapping can be started. We adopt the conventional mapping method, that is, we make a circle around the site environment to form a closed loop. The process is as follows:

▲ slam mapping process ▲

The running speed during drawing construction is 1m / s and the angular speed is 30 ° / s. The map obtained by simply erasing the dynamic objects in the map is as follows:

By zooming in, you can see that the map built with nanoscan3 has straight walls, thin thickness, and no ghosting.

▲ nanoscan3 build map effect ▲

02 actual effective distance test

The nominal maximum effective distance of nanoscan3 is 40m. In the actual test, the correct laser data feedback can be obviously obtained from the wall 40m away from the robot, as shown in the following figure:

03 ranging stability test

For the stability of ranging, we take three cases: long distance, medium distance and short distance.

Long distance (& gt; 30m)

It can be seen from the moving picture that nanoscan3 is excellent in long-distance ranging. The data jump is basically between two map points (about 2cm), and the performance is far superior to similar products.

Medium distance (about 10m)

The data jump of distance in nanoscan3 can be basically ignored (& lt; 1cm).

The accuracy of the data is mainly investigated at a short distance. If the laser processing is not good, it will lead to noise, so the shape of the object cannot be restored correctly. Here, an object with a right angle is used for testing.

Short distance (& lt; 0.1M)

It can be seen that nanoscan3 perfectly restores the shape of the object, does not deform the right angle due to laser noise, and the jump of data is very small.

04 detection of black objects

Nanoscan3 is a safety product. Its detection standard for black objects is very high. It can detect reflectivity of 1More than 0.8% of objects.

We tested using gray black cylinders with diameters of 70mm and 200mm respectively:

▲ the diameters are 70mm and 200mm respectively ▲

The laser is 10cm away from the cylinder

The laser is 3M away from the cylinder

It can be seen that the detection of gray and black objects at different distances by nanoscan3 is also very stable, which can better restore the shape of the object, and there is no case of invalid data points.

05 detection of reflectors

The reflective object test is conducted by using Xianzhi special charging pile to test whether the reflectivity obtained by nanoscan3 is stable at different distances. In the red box below is 3M reflective strip with a length of 18cm.

▲ inside the red frame: reflective strip with length of 18cm ▲

The laser is 10cm away from the reflective strip

In the above figure, the reflectivity of red laser spots is higher than that of green laser spots, which indicates that the laser has detected strip-shaped reflectors, and the reflectors are in a straight line without deformation and noise.

The laser is 2m away from the reflective strip

It can be seen that the strip reflector at 2m is still obvious, and the reflectivity in the laser data remains stable.

It can be seen that the stability of the reflectivity of nanoscan3 data is very excellent. There will be no instability of the reflectivity data at close range, which is significantly better than the same type of lidar on the market, which is very friendly to the relevant applications of identifying reflective objects.

In order to test the longest distance detected by the reflector, the 10cm diameter reflector in the figure below is used for testing:

▲ reflector with diameter of 10cm ▲

After testing, reflective columns with a diameter of 10cm can be stably detected within a range of about 20m (ensuring two high reflective points). The black points in the figure below are the detected reflective columns.

06 foreground noise test

As shown in the figure below, if there is a columnar object at the red dot, at this time, part of the beam that should have scanned the wall will be blocked by the columnar object. Because the laser beam is not a point, but a spot with size, half of the spot will hit the wall and the other half of the spot will hit the columnar object in front. In this case, the foreground noise of the laser is generated.

▲ generate laser foreground noise ▲

The following figure shows the serious foreground noise generated by other brands of lidar, which will directly affect the normal operation of the latent traction robot.

▲ testing of other brands ▲

We simulated a similar situation and tested nanoscan3:

▲ nanoscan3 test ▲

As can be seen from the above dynamic diagram, although nanoscan3 produces foreground noise, there will only be one noise point in one direction, which has no great impact on practical applications. This, thanks to sicks safehddm? High precision measurement patented technology.

[IV. summary]

After in-depth testing, Xianzhi believes that the new product nanoscan3 of sick is a very excellent product, and its superior performance helps slam technology to be better applied to mobile robots. Moreover, nanoscan3 is a product that takes into account safety functions. Combined with the Flexi soft suite of sick and the src-2000 (s) controller of Xianzhi, it can quickly build a mobile robot product that meets the CE safety standard.

About Xianzhi

Xianzhi robot is a high-tech enterprise with mobile robot control and scheduling as the core. As a one-stop mobile robot scheme expert, Xianzhi robot has mastered the core technology of mobile robot with independent intellectual property rights, and has rich project experience in the field of industrial automation. Xianzhi robot is committed to serving industry integrators and providing them with one-stop mobile robot solutions including mobile robot control, scheduling and information management.

At present, the products, technologies and solutions of Xianzhi robot have been widely used in automobile manufacturing, home appliance manufacturing, 3C electronic manufacturing, semiconductor manufacturing, food and tobacco, e-commerce storage, security inspection, commercial services, medical education and other fields.

Xianzhi robot actively implements its corporate mission - "let intelligence create value", constantly adheres to technological innovation, and works with partners in an open, inclusive and win-win attitude, so as to meet customers high-quality pursuit of products, technologies and solutions to the greatest extent, and strive to "become an innovator and leader in the robot industry!"