Fan Cheng Interpretation of Schunk products | application method of rota TP pneumatic chuck

Published on:2020-04-21

Pneumatic chuck is widely used in many fields, such as lathe, drilling machine, machining center, welding equipment and other special equipment. Compared with hydraulic chuck, pneumatic chuck does not need additional supporting equipment, and the power source is cleaner. It is also suitable for applications in automation industry. XiongKe pneumatic chuck rota TP can be used for rotary applications, rota TPS is used for fixed use on processing centers, and TB series is mainly used for pipeline processing in the petroleum industry.

Schunk rota TP pneumatic chuck is internally integrated with driving cylinder and pressure maintaining function. In machine tools or automatic production lines that are not suitable for using hydraulic system, the self centering clamping of workpieces can be realized only by supplying air through the air distribution ring. After the air distribution ring is cut off, the two-way pressure retaining valve of the chuck can maintain the pressure in the chuck cylinder to ensure that the chuck clamping force is stable and reliable during processing.

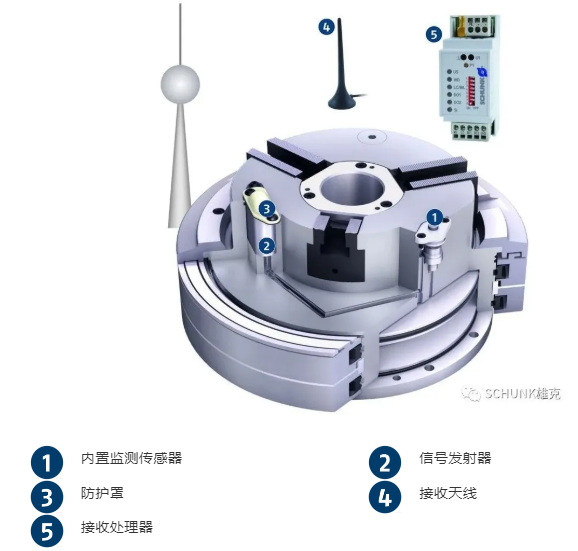

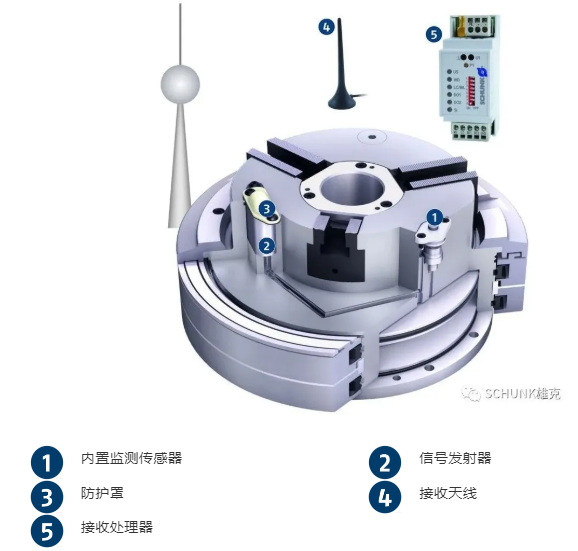

When the automatic production line needs safety monitoring, the rota TP chuck can also be equipped with rss-p1 wireless monitoring of clamping force.

Details of rota TP chuck rss-p1 wireless monitoring system

Working principle of rota TP chuck

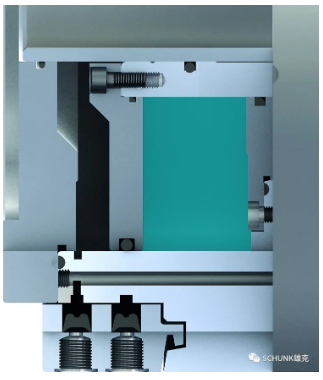

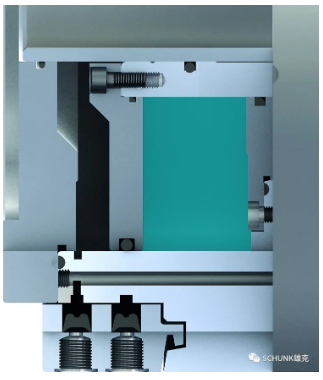

The valve ring of XiongKe rota TP pneumatic chuck can prevent the winding of air supply pipeline.

When the inside of the valve ring is ventilated, the internal special-shaped seal ring will be deformed by pressure and hold tightly on the outer diameter of the chuck body. The compressed air is introduced into the chuck through the air hole in the special-shaped seal ring to drive the chuck.

After the air distribution ring stops venting, the pressure maintaining valve inside the chuck maintains the pressure to permanently maintain the compressed air in the piston cavity, so as to ensure that the chuck always maintains the clamping force in the clamped or loosened state.

The special-shaped sealing ring inside the valve ring rebounds due to the characteristics of the material itself, separates from the outer diameter of the chuck and rebounds to the initial position. The special-shaped sealing ring does not produce any rotation interference with the chuck body.

Installation of valve ring

The main part of the Schunk rota TP pneumatic chuck can rotate, while the external valve ring cannot rotate. Therefore, during installation, a mounting bracket needs to be made on the outside to fix the valve ring to prevent the valve ring from rotating and being damaged by eccentric wear. Schunk rota TP chuck valve ring provides three fixed installation schemes:

1 fork type fixing method

It is only suitable for occasions where the chuck does not rotate or the speed is very low.

2 fixing method of connecting ring

It is suitable for all rotating and non rotating occasions. It is recommended to fix it in this way.

3 lateral locking type

Used in specific occasions.

Precautions for use

Continuous ventilation is not required during rotation. Under normal use, it is forbidden to drive the chuck by ventilation during the rotation of XiongKe rota TP chuck. Continuous ventilation will damage the valve ring and fixed support.

Keep the driving air pressure sufficient. If the chuck driving air pressure decreases, the chuck clamping force will decrease, and the maximum rotation speed will decrease accordingly.

The maintenance is simple and convenient. There is a special lubricating nozzle on each of the three base claws. XiongKe provides the special lubricating grease linomax for the chuck. It is recommended to inject oil for lubrication every 20 hours.

Company profile

Founded by Friedrich Schunk in 1945, Schunk began as a mechanical workshop. Under the leadership of its son Heinz Dieter Schunk, Schunk has developed into an expert in the field of grasping system and clamping technology and a strong competitor in the global market. At present, the company is operated by the brothers and sisters of Henrik A. Schunk and Kristina I. Schunk, the third generation members of the family.

Nine factories and 34 directly affiliated branches, more than 3500 employees and distribution partners in more than 50 countries and regions around the world ensure an intensive market. With 11000 standard components, scunk provides a wide range of gripping systems and clamping technologies for the global market in a one-stop manner; With 2550 kinds of Schunk manipulators, we provide the market with a comprehensive series of standard manipulator components. The whole grabbing system combination contains more than 4000 components.

The most important buyers are manufacturing enterprises with assembly, handling and metal cutting processes. The customer base includes mechanical engineering, robotics, automation and assembly handling personnel, as well as major automobile brands and their suppliers. Since 2012, legendary goalkeeper Jens Lehmann has been part of the scunk team, conveying the brand image of safety, precision gripping and clamping technology.

Schunk rota TP pneumatic chuck is internally integrated with driving cylinder and pressure maintaining function. In machine tools or automatic production lines that are not suitable for using hydraulic system, the self centering clamping of workpieces can be realized only by supplying air through the air distribution ring. After the air distribution ring is cut off, the two-way pressure retaining valve of the chuck can maintain the pressure in the chuck cylinder to ensure that the chuck clamping force is stable and reliable during processing.

When the automatic production line needs safety monitoring, the rota TP chuck can also be equipped with rss-p1 wireless monitoring of clamping force.

Details of rota TP chuck rss-p1 wireless monitoring system

Working principle of rota TP chuck

The valve ring of XiongKe rota TP pneumatic chuck can prevent the winding of air supply pipeline.

When the inside of the valve ring is ventilated, the internal special-shaped seal ring will be deformed by pressure and hold tightly on the outer diameter of the chuck body. The compressed air is introduced into the chuck through the air hole in the special-shaped seal ring to drive the chuck.

After the air distribution ring stops venting, the pressure maintaining valve inside the chuck maintains the pressure to permanently maintain the compressed air in the piston cavity, so as to ensure that the chuck always maintains the clamping force in the clamped or loosened state.

The special-shaped sealing ring inside the valve ring rebounds due to the characteristics of the material itself, separates from the outer diameter of the chuck and rebounds to the initial position. The special-shaped sealing ring does not produce any rotation interference with the chuck body.

Installation of valve ring

The main part of the Schunk rota TP pneumatic chuck can rotate, while the external valve ring cannot rotate. Therefore, during installation, a mounting bracket needs to be made on the outside to fix the valve ring to prevent the valve ring from rotating and being damaged by eccentric wear. Schunk rota TP chuck valve ring provides three fixed installation schemes:

1 fork type fixing method

It is only suitable for occasions where the chuck does not rotate or the speed is very low.

2 fixing method of connecting ring

It is suitable for all rotating and non rotating occasions. It is recommended to fix it in this way.

3 lateral locking type

Used in specific occasions.

Precautions for use

Continuous ventilation is not required during rotation. Under normal use, it is forbidden to drive the chuck by ventilation during the rotation of XiongKe rota TP chuck. Continuous ventilation will damage the valve ring and fixed support.

Keep the driving air pressure sufficient. If the chuck driving air pressure decreases, the chuck clamping force will decrease, and the maximum rotation speed will decrease accordingly.

The maintenance is simple and convenient. There is a special lubricating nozzle on each of the three base claws. XiongKe provides the special lubricating grease linomax for the chuck. It is recommended to inject oil for lubrication every 20 hours.

Company profile

Founded by Friedrich Schunk in 1945, Schunk began as a mechanical workshop. Under the leadership of its son Heinz Dieter Schunk, Schunk has developed into an expert in the field of grasping system and clamping technology and a strong competitor in the global market. At present, the company is operated by the brothers and sisters of Henrik A. Schunk and Kristina I. Schunk, the third generation members of the family.

Nine factories and 34 directly affiliated branches, more than 3500 employees and distribution partners in more than 50 countries and regions around the world ensure an intensive market. With 11000 standard components, scunk provides a wide range of gripping systems and clamping technologies for the global market in a one-stop manner; With 2550 kinds of Schunk manipulators, we provide the market with a comprehensive series of standard manipulator components. The whole grabbing system combination contains more than 4000 components.

The most important buyers are manufacturing enterprises with assembly, handling and metal cutting processes. The customer base includes mechanical engineering, robotics, automation and assembly handling personnel, as well as major automobile brands and their suppliers. Since 2012, legendary goalkeeper Jens Lehmann has been part of the scunk team, conveying the brand image of safety, precision gripping and clamping technology.